Global Customizable PET Film: Why ACS Stands Out In Quality And Versatility

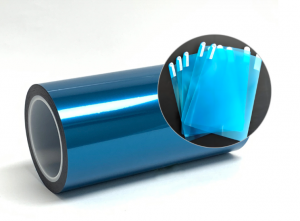

FOSHAN, GUANGDONG, CHINA, January 26, 2026 /EINPresswire.com/ -- The global industrial landscape is experiencing a significant shift toward high-performance materials, with polyethylene terephthalate (PET) film emerging as a cornerstone for sectors including electronics, packaging, and renewable energy. At the forefront of this evolution is Foshan AoChuanShun New Material Industrial Co., Ltd. (ACS), a Global Leading Customizable PET Film Supplier dedicated to providing specialized material solutions. ACS offers an extensive range of PET protective films characterized by exceptional transparency, chemical resistance, and mechanical strength. These products are engineered to meet precise industrial requirements, featuring specialized options such as antibacterial coatings, antistatic properties, and high-temperature resistance, ensuring optimal surface protection and functional performance for global manufacturers.

I. Global Industry Trajectory: The Evolution of Material Science

The technical film industry is currently navigating a period of unprecedented transformation. As global manufacturing moves toward Industry 4.0, the role of substrate materials like PET has transitioned from simple packaging to a critical functional component in high-tech assemblies.

1. The Surge in Optoelectronic Integration

Market analysis indicates that the integration of touch-sensitive interfaces into non-traditional surfaces—such as automotive dashboards, smart home appliances, and medical diagnostic equipment—is driving a specialized demand for optical-grade PET films. These materials must maintain a high light transmittance rate (often exceeding 90%) while providing a robust barrier against environmental degradation. The trend toward foldable and flexible displays has further challenged suppliers to develop films with superior fatigue resistance and dimensional stability under repeated mechanical stress.

2. Decarbonization and the Green Manufacturing Mandate

Environmental sustainability is no longer an optional corporate social responsibility but a regulatory requirement. The industry is witnessing a massive pivot toward "Green PET" initiatives. This includes the development of films with higher concentrations of Post-Consumer Recycled (PCR) content and the transition toward solvent-free adhesive coating processes. Manufacturers are seeking partners who can provide "downgauged" solutions—achieving the same protective properties with thinner gauges—to minimize the overall carbon footprint of the final product packaging.

3. Functionalization Beyond Protection

Modern industrial trends suggest that protection is only the baseline. There is a growing market for "intelligent" films. This includes antistatic (ESD) PET films required for the assembly of semiconductors to prevent electrostatic discharge damage, and antimicrobial films for high-touch public interfaces. The convergence of material science and biochemistry is creating a new sub-sector of functionalized PET that address specialized safety and longevity standards.

II. Institutional Excellence: Engineering Precision and Infrastructure

Foshan AoChuanShun New Material Industrial Co., Ltd. (ACS) has established its market leadership not merely through volume, but through a rigorous adherence to technical standards and a deep-seated culture of research and development.

1. Cleanroom Manufacturing and Contamination Control

A defining factor in the quality of high-precision PET film is the environment in which it is produced. ACS operates an 8,000-square-meter facility centered around Class 1,000 dust-free workshops. In the world of thin-film coating, a single micron-sized dust particle can result in a catastrophic failure for an electronic display. By maintaining stringent air filtration and static control protocols, the facility ensures that film rolls achieve the surface purity required for the most sensitive optical applications.

2. R&D Depth and Customization Architecture

With a core team possessing over 20 years of experience, the enterprise focuses on engineering comprehensive solutions rather than standard commodities. The technical database contains over 6,000 product formulations, a testament to the ability to tailor adhesive peel strength, thermal shrinkage, and surface tension to the specific needs of a client's substrate. High-precision coating lines allow for multi-layer composite structures, enabling the combination of different functional properties—such as scratch resistance on one side and specialized adhesion on the other—within a single profile.

3. Capacity and Consistency at Scale

Reliability in the global supply chain is predicated on the ability to deliver consistent quality at high volumes. With an annual production capacity of 86.4 million square meters, the company utilizes automated thickness-monitoring systems and real-time defect detection technologies. This infrastructure ensures that the first meter of a production run is identical to the last, providing the consistency that 1,500+ global clients rely on for their automated assembly lines.

III. Strategic Application Ecosystems and Global Insights

The versatility of functional materials is best demonstrated through their integration into complex global supply chains, where they serve as essential facilitators of product integrity.

1. High-Precision Electronics and Display Technology

In the competitive consumer electronics sector, PET protective films serve as the primary defense for high-value components during the manufacturing and shipping phases. These films are engineered to leave zero adhesive residue upon removal, a critical requirement for premium smartphone and laptop screens. By utilizing specialized silicone or acrylic adhesives, these solutions can withstand the high-temperature cycles of electronic assembly without bubbling or delaminating.

2. Industrial Graphics and the DTF Revolution

The company has become a pivotal player in the digital textile sector through its DTF (Direct-to-Film) transfer solutions. Unlike traditional screen printing, DTF films facilitate high-definition, multi-color transfers with superior ink absorption and release properties. This allows textile manufacturers to achieve intricate designs with high wash-fastness, supporting the industry's shift toward on-demand, small-batch customized production.

3. Extreme Environment Engineering and Insulation

Beyond surface protection, functional films are utilized in electrical insulation and aerospace applications. Polyimide (PI) tapes and high-temperature resistant PET variants are deployed in environments where thermal stability is paramount. For instance, in EV battery modules, these films provide the necessary dielectric strength to prevent short circuits while occupying minimal space.

4. Surface Protection for Architecture and Automotive Parts

In the automotive and construction sectors, PE and BOPP protective films are used to safeguard high-gloss surfaces, aluminum profiles, and glass panels. By adjusting the film's UV resistance and weatherability, manufacturers ensure that materials stored outdoors or transported across different climate zones remain pristine until they reach the end consumer.

Conclusion

As global demand for sophisticated surface protection and functional materials continues to rise, the importance of precision manufacturing and customizable solutions remains paramount. Through the integration of decades of industry expertise with advanced clean-room production capabilities, Foshan AoChuanShun New Material Industrial Co., Ltd. (ACS) provides the essential substrates that drive innovation in electronics, logistics, and textiles. By focusing on quality stability and versatile applications, the company remains a pivotal contributor to the global supply chain, ensuring that manufacturers can meet the rigorous standards of the modern market.

For more information regarding product specifications and customized film solutions, please visit the official website: https://www.acs-plasfilm.com/

I. Global Industry Trajectory: The Evolution of Material Science

The technical film industry is currently navigating a period of unprecedented transformation. As global manufacturing moves toward Industry 4.0, the role of substrate materials like PET has transitioned from simple packaging to a critical functional component in high-tech assemblies.

1. The Surge in Optoelectronic Integration

Market analysis indicates that the integration of touch-sensitive interfaces into non-traditional surfaces—such as automotive dashboards, smart home appliances, and medical diagnostic equipment—is driving a specialized demand for optical-grade PET films. These materials must maintain a high light transmittance rate (often exceeding 90%) while providing a robust barrier against environmental degradation. The trend toward foldable and flexible displays has further challenged suppliers to develop films with superior fatigue resistance and dimensional stability under repeated mechanical stress.

2. Decarbonization and the Green Manufacturing Mandate

Environmental sustainability is no longer an optional corporate social responsibility but a regulatory requirement. The industry is witnessing a massive pivot toward "Green PET" initiatives. This includes the development of films with higher concentrations of Post-Consumer Recycled (PCR) content and the transition toward solvent-free adhesive coating processes. Manufacturers are seeking partners who can provide "downgauged" solutions—achieving the same protective properties with thinner gauges—to minimize the overall carbon footprint of the final product packaging.

3. Functionalization Beyond Protection

Modern industrial trends suggest that protection is only the baseline. There is a growing market for "intelligent" films. This includes antistatic (ESD) PET films required for the assembly of semiconductors to prevent electrostatic discharge damage, and antimicrobial films for high-touch public interfaces. The convergence of material science and biochemistry is creating a new sub-sector of functionalized PET that address specialized safety and longevity standards.

II. Institutional Excellence: Engineering Precision and Infrastructure

Foshan AoChuanShun New Material Industrial Co., Ltd. (ACS) has established its market leadership not merely through volume, but through a rigorous adherence to technical standards and a deep-seated culture of research and development.

1. Cleanroom Manufacturing and Contamination Control

A defining factor in the quality of high-precision PET film is the environment in which it is produced. ACS operates an 8,000-square-meter facility centered around Class 1,000 dust-free workshops. In the world of thin-film coating, a single micron-sized dust particle can result in a catastrophic failure for an electronic display. By maintaining stringent air filtration and static control protocols, the facility ensures that film rolls achieve the surface purity required for the most sensitive optical applications.

2. R&D Depth and Customization Architecture

With a core team possessing over 20 years of experience, the enterprise focuses on engineering comprehensive solutions rather than standard commodities. The technical database contains over 6,000 product formulations, a testament to the ability to tailor adhesive peel strength, thermal shrinkage, and surface tension to the specific needs of a client's substrate. High-precision coating lines allow for multi-layer composite structures, enabling the combination of different functional properties—such as scratch resistance on one side and specialized adhesion on the other—within a single profile.

3. Capacity and Consistency at Scale

Reliability in the global supply chain is predicated on the ability to deliver consistent quality at high volumes. With an annual production capacity of 86.4 million square meters, the company utilizes automated thickness-monitoring systems and real-time defect detection technologies. This infrastructure ensures that the first meter of a production run is identical to the last, providing the consistency that 1,500+ global clients rely on for their automated assembly lines.

III. Strategic Application Ecosystems and Global Insights

The versatility of functional materials is best demonstrated through their integration into complex global supply chains, where they serve as essential facilitators of product integrity.

1. High-Precision Electronics and Display Technology

In the competitive consumer electronics sector, PET protective films serve as the primary defense for high-value components during the manufacturing and shipping phases. These films are engineered to leave zero adhesive residue upon removal, a critical requirement for premium smartphone and laptop screens. By utilizing specialized silicone or acrylic adhesives, these solutions can withstand the high-temperature cycles of electronic assembly without bubbling or delaminating.

2. Industrial Graphics and the DTF Revolution

The company has become a pivotal player in the digital textile sector through its DTF (Direct-to-Film) transfer solutions. Unlike traditional screen printing, DTF films facilitate high-definition, multi-color transfers with superior ink absorption and release properties. This allows textile manufacturers to achieve intricate designs with high wash-fastness, supporting the industry's shift toward on-demand, small-batch customized production.

3. Extreme Environment Engineering and Insulation

Beyond surface protection, functional films are utilized in electrical insulation and aerospace applications. Polyimide (PI) tapes and high-temperature resistant PET variants are deployed in environments where thermal stability is paramount. For instance, in EV battery modules, these films provide the necessary dielectric strength to prevent short circuits while occupying minimal space.

4. Surface Protection for Architecture and Automotive Parts

In the automotive and construction sectors, PE and BOPP protective films are used to safeguard high-gloss surfaces, aluminum profiles, and glass panels. By adjusting the film's UV resistance and weatherability, manufacturers ensure that materials stored outdoors or transported across different climate zones remain pristine until they reach the end consumer.

Conclusion

As global demand for sophisticated surface protection and functional materials continues to rise, the importance of precision manufacturing and customizable solutions remains paramount. Through the integration of decades of industry expertise with advanced clean-room production capabilities, Foshan AoChuanShun New Material Industrial Co., Ltd. (ACS) provides the essential substrates that drive innovation in electronics, logistics, and textiles. By focusing on quality stability and versatile applications, the company remains a pivotal contributor to the global supply chain, ensuring that manufacturers can meet the rigorous standards of the modern market.

For more information regarding product specifications and customized film solutions, please visit the official website: https://www.acs-plasfilm.com/

Foshan Ao Chuan Shun New Materials Industry Co., Ltd.

Foshan Ao Chuan Shun New Materials Industry Co., Ltd.

+86 189 2485 4433

daphne@aochuanshun.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.